Table of Contents

Heat Exchanger Design Service in UK

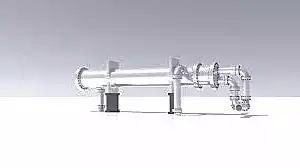

KKR Bose Design provides Heat Exchangers Design services to meet your requirements. Our heat transfer challenges are addressed through an innovative and effective approach to achieve maximum performance, improve energy efficiency, and optimization of the system. We design professional designs that surpass the performance and reduce the energy consumed by the system and

maximize the system efficiency, with the help of our highly skilled engineering team. We do thorough analyses Pressure Vessels, and Long Columns by using advanced software tools such as PV-ELITE, generating accurate calculations and detailed drawings for Nozzle Load Calculation, Support Drawings, Welding Drawings, GAD Drawings, etc and detailing Shell Development Drawings, Nameplate Designs including Ladder, Platform drawings, Handrail partitions etc.

In addition, through these clients, we provide services in the major UK industrial hubs like Manchester, Bristol, Leeds, and Aberdeen to deliver industry leading heat exchanger designs for energy efficient use and system performance.

Why KKR Bose Design is a Leading Choice for Heat Exchanger Design Services:

Expert Engineering: Our team of expert engineers at KKR Bose Design, has years of experience in designing of heat exchanger, providing our expertise in creating dependable and efficient solutions for our clients. At Advance, we have specialised in offering UK wide high quality engineering solutions for industries in Manchester, Bristol, Leeds and Aberdeen.

We Know that every heat transfer application is unique. Therefore, we work to tailor using our designs to achieve optimum performance and operation, with the basic requirement of each of our clients addressed. We design the most suitable design for your requirements whether you are in oil & gas, power generation or chemical processing.

The latest simulation and design tools available are utilized to provide you with the best accurate designs and optimize the thermal performance of EST-RAC units to provide the most efficient and accurate designs. Using our advanced tools – PV-ELITE – we offer standards in line with international ones and UK’s regulatory requirements.

Performance Optimization: We try to increase system performance with less cost of materials, part specifications, and optimization process. Our expertise in this area is supporting our team to make sure that each heat exchanger is operating the way it’s supposed to and operating efficiently, which also means reducing the risks and operation costs.

Energy Efficiency: We strive to enhance energy efficiency with our designs as it contributes to lowering operational costs among other solutions that are sustainable and eco friendly. Optimization of heat transfer processes and minimization of energy consumption allows you to reduce your cost and have a positive impact on the environment.

Our Heat Exchanger Design Process:

- We at KKR Bose Design perform needs assessment, in the beginning, and evaluate the thermal requirement of your applications and determine the heat transfer rate and system specification. We work hand in hand with you to understand your particular requirements and undertake to achieve the necessary performance criteria in the design of that system or service. We focus in several industries around the UK, such as Manchester, Glasgow, London and even Sheffield, and assess in a way that best fits the shape of your operational environment.

Our engineers prepare preliminary designs taking care of flow rate efficiency, material selection and selection of thermal characteristics of components for best performance. We call all the variables that will impact it going forward no matter whether a chemical plant in Birmingham or an energy facility in Aberdeen.

Proposed designs are severely simulated and analyzed to see how much better they can be optimized. Simulation of heat transfer, analysis of compatibility of materials, and evaluation of structural safety is accomplished through the use of advanced tools such PV-ELITE. We make sure that our designs match UK and international industry’s standards.

Final Design: It’s then that we produce complete manufacturing drawings and specifications to enable its manufacturing and installation smoothly. All our designs are afforded detailed GAD drawings, nozzle load calculations and other such, but can be exported as is lettering, welding drawings, or anything that will assist with the construction and installation on site, in a manufacturing plant in Bristol or power generation in Leeds.

Industries We Serve with Our Heat Exchanger Design Expertise:

- Petrochemical

- Power Generation

- HVAC & Refrigeration

- Oil & Gas

- Food & Beverage

- Pharmaceutical

- Chemical Processing

Partner with KKR Bose Design for best Thermal Design Solutions.

Get in touch with us for the Heat Exchanger Design Services to overcome the thermal design issues with KKR Bose Design. We gainfully leverage our innovative, efficient solutions to optimize heat transfer and energy efficiency and ensure long term performance of the system in various industries. The team comprises of our experts who are spread around Leicester, London, Manchester and Glasgow and we ensure that our designs meet your operational requirements.

If you want to see how we can improve the performance and costs of your heat exchanger systems, talk to out experienced engineers today. Your heat transfer solution will be optimised together with us to deliver the success of your projects.

Advantages of Choosing KKR Bose Design for Heat Exchanger Services:

- Competitive Pricing: Affordable pricing structures without compromising on quality.

- High-Quality Performance: We provide top-notch performance-driven solutions.

- Innovative Techniques: Utilization of the latest technologies and proven methodologies.

- Timely Response: Quick responses to all service-related queries.

- On-Time Project Delivery: We ensure timely completion and delivery of projects.

- Customer Satisfaction Guaranteed: Your satisfaction is our priority.

- Qualified Professionals: Our team consists of skilled and experienced engineers.

KKR Bose Design’s Comprehensive Heat Exchanger Solutions:

KKR Bose Design provides Heat Exchanger Design Services that include:

They provide the Thermal Analysis as well as the Mechanical Calculations of all types of heat exchangers for achieving the maximum performance and efficiency.

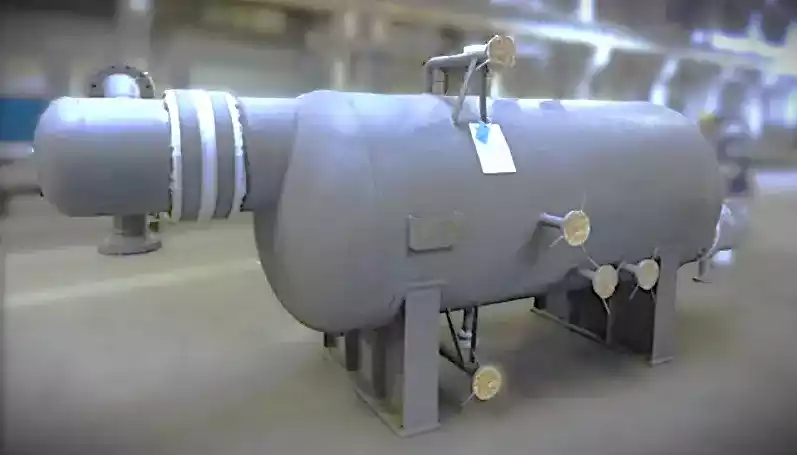

Pressure, temperature and flow optimization of Shell and Tube Heat Exchanger Design.

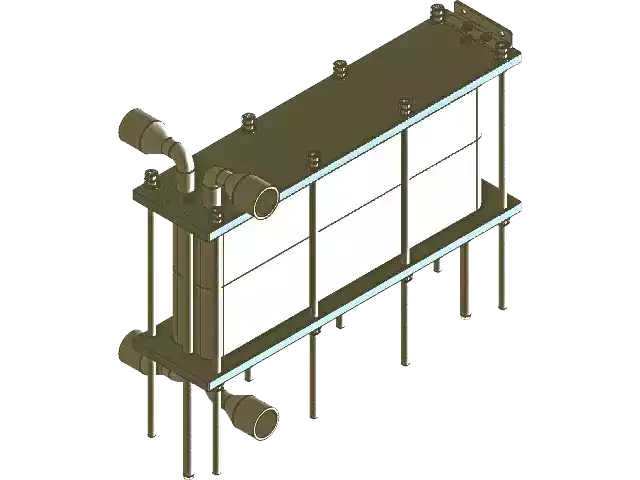

Concepts for Plate Type Heat Exchanger Design seeking compactness, low cost, and increased heat transfer.

The analysis of the Cooling System used to provide operational efficiency in Oil and Gas, Power Plant and Manufacturing industries.

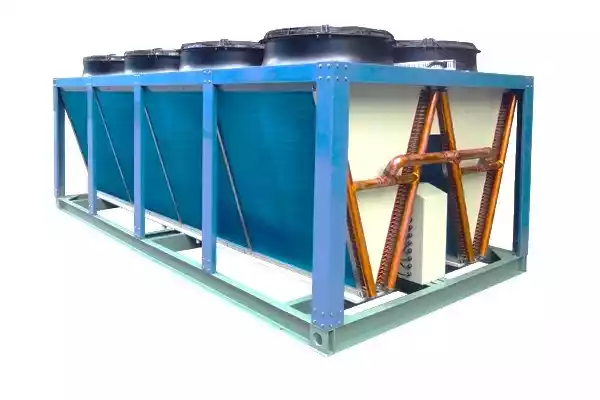

In addition, we offer detailed Mechanical Calculations of air coolers and other types of heat exchanger variants based on international standards and correlating system performance.

KKR Bose Design can assist you in designing optimum heat exchange systems for highest energy saving and reliability and we have expert solutions for your individual requirements.

We specialize in several types of heat exchangers, such as:

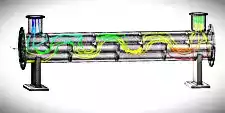

- Shell and Tube Heat Exchangers

- Double Pipe Heat Exchangers

- Plate Heat Exchangers

- Condensers, Evaporators, and Boilers

- Other Heat Exchanger Variants: Including Coil Type, Compact Plate, and Plate Fin Heat Exchangers.

KKR Bose Design's Global Presence and Expertise:

With over 13 years of industry expertise, KKR Bose Design has established itself as one of the leading Heat Exchanger Design Consultancies. Our operations span across multiple regions, including:

- India

- United States (US)

- Dubai (UAE)

- Middle East

- United Kingdom (UK)

Petroleum heat exchangers involve Shell and Tube Heat Exchangers and Plate Type Heat Exchangers, we have enough experience to develop precise design calculations and CAD drawing. At our team, we ensure that the designs we produce are of high quality, consistent, energy efficient and designed only to the needs of every client to get the best thermal performance and system efficiency possible.

To provide you with heat exchanger design that is technically excellent and globally accepted, trust KKR Bose Design.

THERMAL & MECHANICAL Calculation for SHELL AND TUBE HEAT EXCHANGERS:

KKR BOSE DESIGN is a pioneering consultancy firm having successfully served the heat exchanger industry for over 13 years. We have a broad range of expertise covering various types of heat exchangers such as:

– Shell and Tube Heat Exchangers

– Plate Type Heat Exchangers

– Coil Type Heat Exchangers

– Compact Plate Heat Exchangers

– Double Pipe Heat Exchangers

– Plate Finned Heat Exchangers

We have the operations spread across the Globe, including India, United States (US), Dubai (UAE), Middle East and, United Kingdom (UK).

Petroleum Heat Exchangers We provide design calculations and CAD drawings specifically for Shell and Tube and especially Plate Type Heat Exchangers, completely meeting all thermal efficiency, reliability and superior performance standards.

For a reliable partner that provides top of the line heat exchanger solutions for your industry’s specific requirements, choose KKR Bose Design.

KKR Bose Design’s Heat Exchanger Design Services Include:

- Fixed Tube Sheets

- U Tube

- Floating Head Tube Sheet

- Coaxial Tubes

- Kettle Type Re-boiler

- Finned Tubes

- Shell and Tube Exchangers

- Plate Type Heat Exchangers

KKR Bose Design Scope of Work:

At t KKR Bose Design, we offer Heat Exchanger Design services with first class quality, as per the highest industry standards, including:

ASME Section VIII Div 1 & Div 2

TEMA (Tubular Exchanger Manufacturers Association)

API-660 (Shell and Tube Heat Exchangers for Refining and Petrochemical Plants)

API-661 (Air Cooled Heat Exchangers)

To ensure that all heat exchanger systems are safe, reliable and efficient, we have a highly experienced design team that guarantees all designs are to these stringent standards.

For all kinds of heat exchangers including Shell and Tube, Plate Type, Air Cooled, etc., we provide detailed drawings regarding engineering and fabrication. These drawings contain all the specific specifications for manufacturing and installation and ensure for execution without problem and conformity with all safety and quality requirements.

Working with KKR Bose Design means working with a standards compliant process of heat exchanger design, assuring optimized performance, safety and durability of your heat exchanger systems.

Features of KKR Bose Design’s Heat Exchanger Services:

If you are looking for customized Heat Exchanger design and some highly efficient they, there is no doubt that at KKR Bose Design you will get an ideal solution for your applications.

Our Heat Exchanger Design Services Key Features:

- We offer flexible designs to work with your specific operational needs to create the best possible fit for your system requirements and application requirements.

- Our designs are designed to be well suited to industrial environments with difficult circumstances with extreme temperature capabilities and high pressure capabilities.

- Advanced Software: Our thermal and mechanical design is done using industry standard HTRI and PV Elite software. With these tools, we can optimize the heat transfer efficiency, yet we must be certain that we have safety and reliability.

- EDR & Aspen One Engineering Tools: These tools are used for heat exchanger rating and performance analysis in depth and gives heat transfer rate, pressure drop and overall system efficiency.

- Flow Induced Vibration Analysis Solutions: To avoid necessary issues like flow induced vibration, scaling, reduced heat transfer efficiency, we implement special vibration analysis to increase the durability and performance of the system.

KKR Bode Design offers you innovative and reliable highly efficient heat exchanger solutions to help you optimize your systems to full performance and longevity no matter how harsh your industrial settings.

Comprehensive Heat Exchanger Solutions We Provide:

Therefore, KKR Bose Design provides heat exchanger design service of a full spectrum to cater various industries’ needs. We have a vast expertise in all sorts of heat exchangers to satisfy our customers’ needs of maximum thermal and mechanical performance.

- Shell and Tube Heat Exchangers: We offer full thermal and mechanical design and rating services as well as complete fabrication drawings to satisfy your requirements for an efficient shell and tube heat exchanger in harsh environments.

- Our team is specialized in thermal design and rating services for air cooled heat exchangers, making optimum use of air as cooling medium in Air cooled Heat Exchangers.

- Plate-Fin Heat Exchangers: We provide thorough analysis and design solution for plate-fin exchangers that offer compact, high performance systems for efficient heat transfer.

- Our Complete Design and Rating Services of Double-Pipe Heat Exchangers Sufficiently Allows for the Optimization of Heat Exchange Between 2 Seperated Fluids for Guaranteed Reliability and Efficiency.

- Thermal Integration: Pinch Analysis and heat integration to optimize exchangers use and utilities flow to decrease energy and enhance the system efficiency, as well as reduce the operational costs.

Having more than 13 years of deep industry knowledge KKR Bose Design offers the best heat exchanger solution with latest technology, proven, cost effective and dependable heat exchanger solution customized for your specific operation. Regardless of the shell and tube, air cooled or plate fin exchanger, we make sure to have each system optimised for the highest efficiency and most performance.

Heat Exchanger Network Design:

Specilizing in optimizing Heat Exchanger Networks for Industrial applications we have the ability to service the major UK industrial hubs of London, Manchester, Birmingham & Glasgow. Through process and design evaluations of the network, our services enable us to place heat exchangers, flows of utilities, and system configurations. We offer Heat Integration and Pinch Analysis services necessary to maximally increase energy efficiency, reduce the number of exchangers needed, and improve the performance of the utilities by reducing the overall operating cost.

Additionally, we provide broad verification of FEED (Front End Engineering Design) and designs to make certain that they satisfy execution performance necessities. What this rigorous approach does, is that it allows you to refine your designs to deliver cost and efficient heat exchange offerings matching your plant’s exact heat exchange needs.

Some of the heat exchangers, that are efficiently designed using the thermal design services offered by KKR Bose Design are:

• Thermal Design of Fixed Tube Sheet Shell and Tube Heat Exchangers

• Shell and Tube Heat Exchanger Thermal Design Services

• Reboiler Design Services

• Comprehensive Shell and Tube Heat Exchanger Designing Services (STHE)

We are proud to supply cutting edge heat exchanger design solutions throughout the UK from Bristol to Leeds and the Oxford Science Park. As a leading designer and manufacturing company of lifting equipment, our main purpose is to assist clients in the improvement of their operational efficiency and sustainability, and we have a strong position in major industrial centers. With KKR Bose Design, your heat exchanger design and integration processes can be guided and designed for optimal performance and cost saving across the UK’s varied industrial industries.

Codes & Standards We Follow:

- ASME Section VIII Div I and Div II

- TEMA (Tubular Exchanger Manufacturers Association)

- API 660

- PD 5500

- British Standards

- Indian Standards

- Australian Std. AS 1210

- GOST

- AD Merkbklatt

- PED 97/23/EC (CE Marking)

Our heat exchanger design services at KKR Bose Design are reliable, efficient and cost effective and will help improve the status of your projects. Whether you need the calculations to aid your thermal analysis, mechanical calculations, or have a need for completely detailed CAD drawings, we can fulfill any need. Do not hesitate to contact us and we will provide the best solution for your heat transfer applications.

- Heat recovery heat exchangers design,

- Ambient air vaporizer design

- LNG vaporizer design

- Liquid Nitrogen, Liquid Oxygen vaporizer design

- Open rack vaporizer design

- Submerged Combustion Vaporizer design

- Shell & Tube Vaporizers

- Double pipe heat exchangers design

- Oil cooler heat exchangers design

- Air heated heat exchanger design

- Steam condenser heat exchanger design

- Air-Cooled Condenser for Steam Condensation Design HTRI

- Dynamic Modeling of Steam Condenser and Design

- Air conditioner condenser & evaporator design

- Intercooler & After Cooler heat exchanger design

- Feed water heater design & engineering

- Open and closed feed water heater design

- Thermal power plants feed water heaters design

- Boiler Feed water Heaters design

- LP / HP Boiler Feed water Heaters design

- Feed water Heater in Steam Power Plant design

- Feed water heater (LP/HP) – Shell and tube heat exchangers

- Feed water heaters for motor ships design

- Feed water Heater Tubes thermal design

- Air Conditioning – condenser & Evaporator design

- Oil cooled Shell and tube heat exchangers design

- Oil cooled all type of Heat Exchangers design

- Lube Oil Cooler Heat Exchanger design

- Oil/water cooled plate heat exchanger PHE design

- Hydraulic Oil Coolers (cooled) Shell and Tube Heat Exchanger design HTRI

- Oil Coolers for lubrication equipment design – Heat Exchangers –

- Turbine Lube Oil System all type of Heat Exchangers design. HTRI

- Engine Oil Coolers & all type of Heat Exchangers design

- Transformer-oil-cooler & all type of Heat Exchangers design

- Fan, Radiator, Coolant Recovery System, Heat Exchangers design HTRI

- Rice Mill Heat Exchangers design

- Pulp and paper industry heat exchangers design

- Oil & gas industry all heat exchangers design

- Refineries all heat exchangers design

- Petrochemicals all type of heat exchangers design.

- Thermal power plants all type of heat exchangers design

- Hydraulic power plants all type of heat exchangers design

- Nuclear power plants all type of heat exchangers design HTRI

- Fertilizer industries all type of heat exchangers design

- Dry wood pulp in pulp and paper mill steam coils design HTRI

- Welded plate Heat exchangers design for pulp and paper industry.

- Heat recovery heat exchanger design for pulp and paper industry.

- Plate heat exchangers,

- Spiral heat exchangers design HTRI

- Evaporation of sewage heat exchanger design

- Cooling of sewage heat exchanger design

- cooling of hydraulic oil heat exchanger design

- motors and gearboxes cooling heat exchanger design HTRI

- heating of steam process water heat exchanger design

- heat exchangers used in the offshore industry

- shell and tube exchangers;

- plate heat exchangers comprising a stack of thin plates;

- double pipe heat exchangers;

- and condensers, evaporators, and boilers.

- Heat exchanger design for preheating

- Air-Cooled Condenser for Steam Condensation Design HTRI

- Dynamic Modeling of Steam Condenser and Design

- Surface condenser design

- Hybrid steam condenser Design

- Steam Condenser Vacuum Calculations

- Steam Condenser: Basics, Parts, Advantages,

- Condensate Recovery System- Steam System

- Design of a steam plant condenser

- Standards for Steam Surface Condensers.

- Software thermal design – Multi Component Condensers

- Turbine Gland Steam Condenser HTRI

- Dump steam condenser

- Vertical-Fluted-Tube Condenser

- Large Steam System Condensers

- Flash steam condenser

- Condenser for steam turbine design HTRI

- Steam Surface Condenser Design

- Flash Steam Vent Condensers design HTRI

- Oil & gas, refineries oil heated heat exchangers design.

- Hot Oil System heat exchangers Design

- Storage tanks Steam Coil design

- Storage tanks Heating Coil Design

- Heating Coil Sizing For Fuel Oil Tank

- Sizing Heating and Cooling Coils for all equipment’s.

- Design of Coil Heat Exchanger

- Heating Coil in The Main Air Handling Unit design

- Crude Oil Storage Tank Heating Coil design

- heat exchanger design for heating and hot water production .

- Plate heat exchangers (PHEs) design

- Heat exchanger design for twisted geometries for biogas process

- U-pipe and Coaxial heat exchangers design.

- Shell and tube heat exchangers design

- Double pipe heat exchangers design

- Plate heat exchangers design HTRI

- Condensers, evaporators, and boilers.

- U-shaped finned heat pipe heat exchanger

- Copper Coaxial Heat Exchanger, Shell & Tube type design HTRI

- Thermal design and optimization of fin-and-tube heat exchanger

- Steam Operated Plate Heat Exchanger design

- Cross flow vs. counter flow heat exchanger design

- Falling Film Exchangers and Evaporators design

- Water Cooled Surface Condenser design

- ROTARY HEAT EXCHANGER design

- Horizontal and Vertical Condensers design

- Compact heat exchangers design

- Shell and tube heat exchanger

- Plate type heat exchangers

- Finned tube heat exchanger

- Compact plate heat exchanger

- Double pipe heat exchanger

- Plate fin heat exchanger

- Plate heat exchanger in oil refineries and oil production design

- Crude preheat train, heat exchanger design

- Crude heat exchanger , Primary distilled oil heat exchanger, Primary overhead oil heat exchanger,

- Overhead oil gas heat exchanger, Overhead oil-water cooler, First-line oil heat exchanger,

- Second-line oil heat exchanger, Third-line oil heat exchanger:

- Heat exchanger design for Heating of fuel-oil, diesel fuel, crude oil, kerosene, HVF, tar, etc.

- Heat exchanger design for Cooling of hydraulic turbine, transformer oil and lube oil

- Heat exchanger design for Heating of natural gas, before or after expansion HTRI

- (to avoid freezing the ground)

- Heat exchanger design for Heating of bitumen and coated materials

- Heat exchanger design for hating, and drying,

- Heat exchanger design for steam generation,

- Heat exchanger design for crude oil cooling

Our engineering services cover a wide variety of design and detailing services * Pressure Vessel Process design * Heat exchanger Thermal design * Heat exchanger design and detailing * Pressure vessel design and detailing * Separator and Deaerator design * Air cooled heat exchangers * Shell and tube heat exchangers * ‘U’ tube heat exchanger * Plate heat exchangers * Storage tanks * Oil coolers and other type of heat exchanger * Mechanical Calculations for all equipments * All type of mechanical parts detailing services Advantages of our Design Services: Some of the completed Heat exchanger works are: VOC Water Cooler for Allied Heat Transfer. * Use of the competitive price structure * Entailing Best quality performance services * Implementation of the most recent technology and techniques * Quick response to any of the service inquiries * Ensuring strict compliance with time table in all projects * Ensuring total customer satisfaction * Professionals and experienced personnel. Australia Exhaust Gas Cooler for Allied Heat Transfer Pulsation Bottle for Allied Heat Transfer Frying Oil Cooler for Allied Heat Transfer Power Station Bearing Oil Cooler for Allied Heat Transfer Spitfire – Air Cooler Heater for Allied Heat Transfer Overhead Condenser for Universal Heat Exchanger India Water Stripper Re–Boiler for Universal Heat Exchanger India U–TUBE Exchanger for Universal Heat Exchanger India Shell and Tube Exchanger for Universal Heat Exchanger India heat Hence with a good mix of experience and skilled CAD draftsmen, we are able to offer excellent quality of drawings that gives us a one-time client, a repeated customer.

Mumbai I Delhi I Kolkata I Chennai I Bangalore I Hyderabad I Ahmedabad I Pune I Seurat I Jaipur I Kanpur I Lucknow I Nagpur I Indore I Patna I Bhopal I Thane I Vadodara I Visakhapatnam

New York I Los Angeles I Chicago I Houston I Phoenix I Philadelphia I San Antonio I San Diego I Dallas I San Jose I Washington I Boston I Las Vegas I San Francisco I England I Birmingham I Glasgow I Liverpool I BristolENG I Manchester I Sheffield I Leeds I Edinburgh I Leicester I Northern Ireland I Scotland I Wales I London I Bradford

Bristol I Wakefield I Cardiff I Coventry I Nottingham I Sunderland I Belfast I Newcastle upon Tyne I Brighton I Hull I Plymouth I Stoke-onTrent I Wolverhampton I Derby I Swansea I Southampton I Salford I Aberdeen I Westminster I Portsmouth I York I Peterborough I Dundee I Lancaster

Oxford I Newport I Preston I St Albans I Norwich I Chester I Cambridge I Salisbury I Exeter I GloucesterLisburn I Chichester I Winchester I Londonderry I Carlisle I Worcester I Bath I Durham I Lincoln I Hereford I Armagh I Inverness I Stirling I Canterbury I Lichfield I Newry I Ripon

Bangor I Truro I Ely I Wells I St Davids I Antigua and Barbuda I Australia I The Bahamas I Barbados I Belize I Canada I Dominica I Grenada I Guyana I Ireland I Jamaica I Malta I New Zealand I St Kitts and Nevis I St Lucia

St Vincent and the Grenadines I Trinidad and Tobago I United Kingdom I United States of America I Toronto I Ontario I Quebec I Vancouver I British Columbia I Calgary I Alberta I Ottawa I St. John’s I Newfoundland I Charlottetown

Prince Edward Island I Saskatoon I Saskatchewan I Whitehorse I Yukon I Halifax I Nova Scotia I Banff I SYDNEY I MELBOURNE I BRISBANE I PERTH I ADELAIDE